HMT - Häseler Metall Technik

Now also evaluates waste heat with econ

HMT has been using the system from econ solutions to record and evaluate energy data for a good ten years. Now waste heat has been added.

The Energy Efficiency Act obliges companies with a total energy consumption of more than 2.5 GWh/a to report data on waste heat potential to the waste heat platform. They must also avoid or reuse waste heat wherever possible. However, this was not the only reason why HMT wanted to integrate waste heat data into its econ energy management system.

HMT specializes in precise and sophisticated complete solutions in the field of stamping and forming technology as well as industrial parts cleaning. During cleaning, the parts are first cleaned in two large systems and then dried in drying ovens. The warm exhaust air produced here has so far been discharged unused to the outside.

Internal considerations regarding the use of the waste heat resulted in two options: returning the thermal output to the cleaning process or using the heat for the upcoming renovation of the company building's heating and ventilation system.

In order to decide which option to pursue, HMT needed to know how much waste heat was actually available. We recommended Luftmeister 's measurement technology for this purpose.

Simple integration

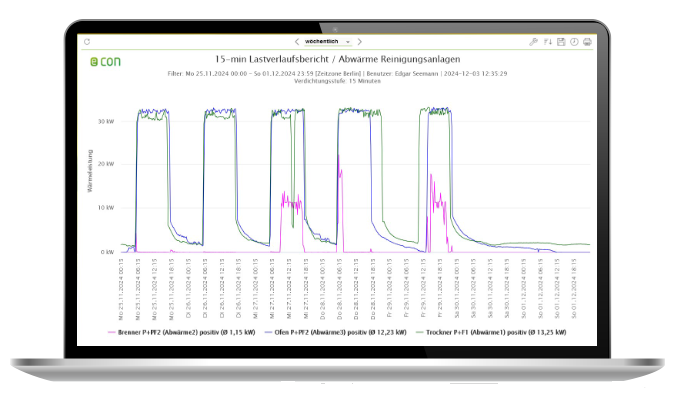

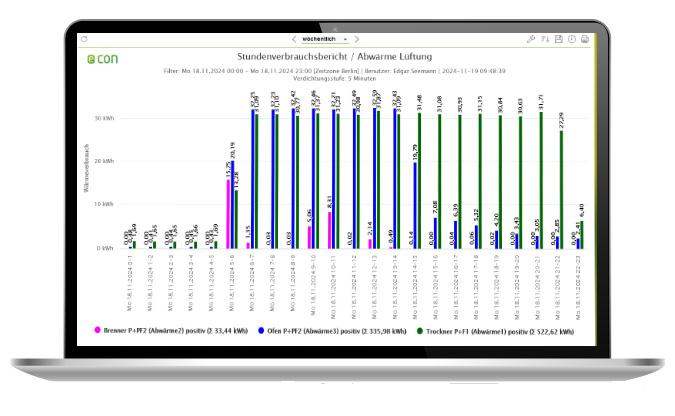

The measuring devices have now been installed and the data is integrated into econ's energy management system via a Modbus interface: "It was a good team effort," reports Edgar Seemann, Energy Management Officer (EMO) at HMT until the end of 2024. "Our in-house electrician laid the cables to the Luftmeister devices and the econ unit data logger, Luftmeister configured the measuring devices and econ integrated them into the energy management software. It all worked perfectly." This enables HMT to visualize the thermal output, temperature, volume flow, absolute pressure and enthalpy of the waste heat in the econ4 software.

The initial evaluations have already provided an important insight: the amount of heat in the exhaust air from the drying ovens is much lower than expected in some places. "Presumably because the flow velocity there is relatively low," says Philip Menius, the new Energy Management Officer (EMO) at HMT. Further data will provide more transparency on this.

Menius is also passing on the waste heat data to the heating company, which is planning a new heating and ventilation system on this basis. According to current calculations, a conventional system would have a much longer payback period than a heat pump, which would be used for both heating and cooling. Compared to the current system, the costs for heating with a heat pump and the use of waste heat would be more than halved.

System grows according to demand

In addition to waste heat, HMT recently integrated sensors for recording temperature and humidity in some parts of the building into the econ energy management system, as well as measuring devices for water quantities. In addition, HMT already monitors electricity, process gas and the heat input from a combined heat and power plant. "With the econ system, we have a lot of options for displaying the measurement data," says Philip Menius. "For example, we can look at different time periods or make comparisons from plant to plant."

HMT finds the annual approach particularly helpful. "This allows us to compare situations that occur repeatedly; on the other hand, we can see the changes in consumption when a situation changes, for example when there are changes in shift operation. Because HMT has been using econ for so long, we can also identify trends. This enables us to identify opportunities for optimization and we can create consumption forecasts."

HMT's commercial department also has access to econ4, which it uses, for example, to take appropriate account of energy costs when calculating quotations. "ISO 50001 certification is also on the agenda. HMT has an excellent basis for this with econ. This is also confirmed by the office commissioned to provide support for the certification," reports Edgar Seemann.

I can only say positive things about econ. Even if we have questions or need support, we are always in good hands.

Edgar Seemann, Energy Management Officer (EMO) until the end of 2024 at HMT Häseler Metall Technik